JB Engineering DCP-Anchors

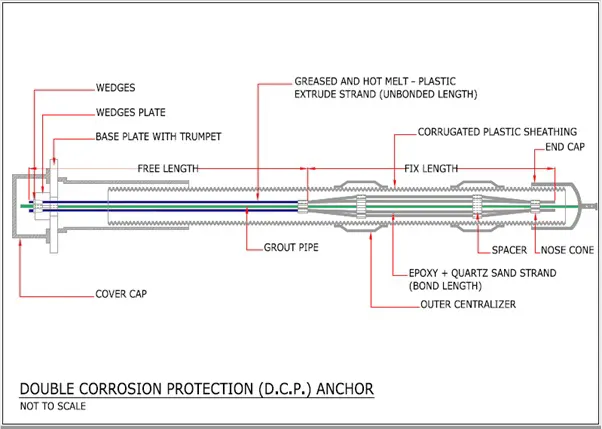

JB Engineering Double Corrosion Protection (DCP) Anchors are HOT DIP ZINC Coated & Fusion EPOXY COATED which provides protection from Corrosion for minimum 100 Years with two independent barriers between the anchor tendon and the environment. Grouted corrugated sheathing with controlled crack width and are for permanent use. Mostly used in high rise construction for heavy reinforcement.

- Ground anchors are unique as they can provide active restraint to the structures.

- Anchors avoid movements by applying a compressive load to a structure.

JB Engineering (DCP) - DOUBLE CORROSION PROTECTION Anchors classifies as like below:

- The application of ground anchors is increasing as they enable construction in densely populated areas. This increase is due to the reductions in available space for traditional construction methods.

- In areas of limited easement, removable anchors can be used. For projects where further underground construction, like adjacent developments of tunnels is anticipated engineers can use resized anchors produced from composite materials. We are top-rated packers and movers in Mohali

Features of DOUBLE CORROSION PROTECTION Anchors are:

- Hot Zinc Coated / Fusion Epoxy Coated anchors provide minimum 100 Years Corrosion Protection.

- Bond length and free length to enable pre-stressing.

- Capacities: bars 4,500 kN, strand15,900 kN(+)

- Anchors with diameter range12-75mm strand anchors up to 63mm(+)

- Full compatibility with infrastructure intelligence, utilizing multiple sensor types.

How ground anchors work: - JB Engineering Pre-stressed grounds Double Corrosion Protection (DCP) Anchors are HOT DIP ZINC Coated & Fusion EPOXY COATED provides protection from Corrosion for Minimum 100 Years & more actively contribute to the stability of a structure throughout its design life. The performance of the anchor is critical to the stability of the structure.

Stressing jacks are used to pre-stress the anchor and elongate the tendon. Once the necessary load has been established, the anchor is locked off at the head. The anchor then applies a compressive load to the structure to arrest movement.

The anchor is un-bonded from the ground between the structure and the load-bearing strata to prevent load from being transferred in to unsuitable material and to ensure that sufficient elongation of the tendon is possible. We are shifting goods product by top rated packers and movers in Mohali. Upon reaching the desired depth, the tendon is directly bonded to the ground, forming the two fundamental elements of the ground anchor: the free length and the bond length.

In permanent work, anchors need to be protected against corrosion in line with internationally recognized anchor design standards. Double corrosion protection (DCP) is provided with HOT DIP ZINC coating process & fusion EPOXY COATED process which provides protection from Corrosion for Minimum 100 years with two independent barriers between the anchor tendon and the environment.

Introducing JB Engineering Smart Technologies:

JB Anchors are the first in a series of smart products developed by JB Engineering.

Applications:

- Uplift control

- Toe stabilization

- Rock stabilization

- Positional stability